The process of disassembly, removing, replacing, and reinstalling parts, as well as, performing preventive maintenance (PM) on the Brand Transferpette S single channel pipette require great care. A high attention to detail, patience, and steady hands are required. Please dedicate a good work area with good lighting and space where small parts can be located should they pop/fly out during disassembly. Pipette damage and lost parts may occur if attention to detail is not maintained. Please proceed at your own risk.

Recommended Supplies

- Pair of gloves (not pictured)

- Transferpette S Silicone Oil item# BT 705502 (for use with up to 1000uL volume sizes)

- Box of Kim Wipes

- Bottle of IPA 70%

- Replacement parts

NOTE: These instructions are for Transferpette S single channel pipettes that are between 2uL-1000uL volume sizes. It’s recommended that a 4-5 place analytical balance be used to check the accuracy and precision performance after PM and 1 hour equilibration period is completed.

Transferpette S Disassembly and Preventative Maintenance

Step 1:

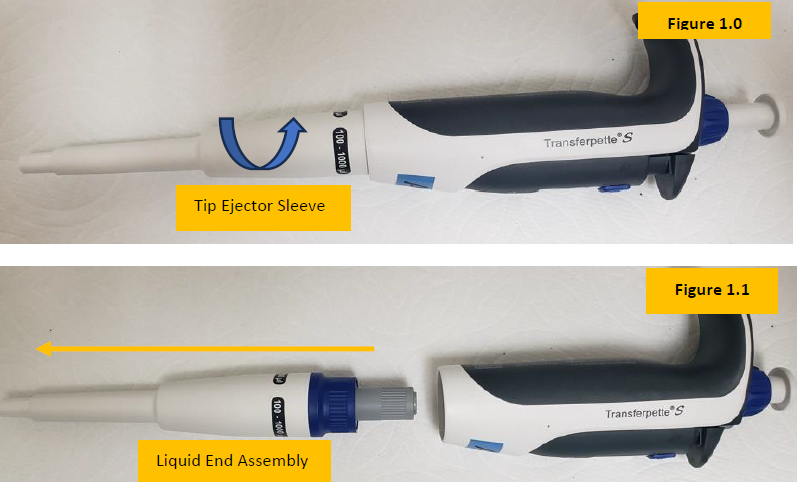

Rotate and unscrew the Transferpette S tip ejector sleeve from the pipette body. See Figure 1.0

Once fully unthreaded, the entire shaft assembly will detach from the pipette body, as shown in Figure 1.1.

Step 2:

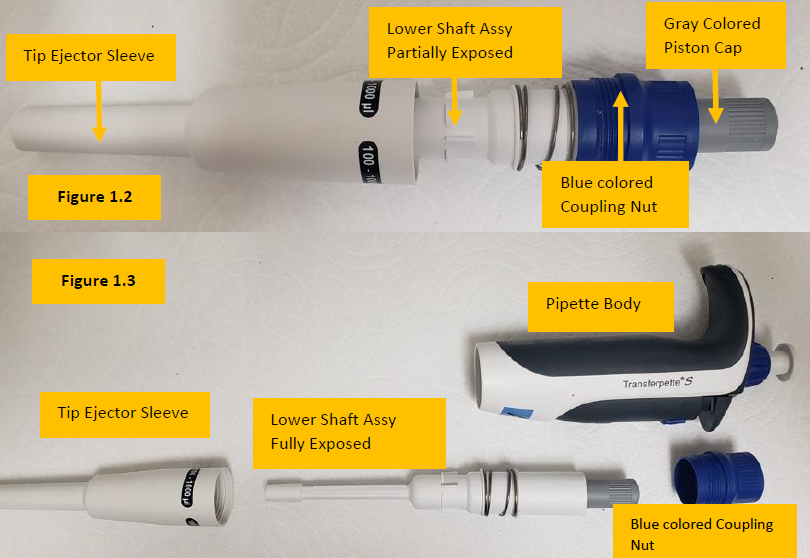

Unscrew the blue colored coupling nut so that the tip ejector sleeve can be removed fully, thus exposing the lower shaft assembly. See Figure 1.2

Observation: Figure 1.3 shows the lower shaft assembly fully visible and separated from the tip ejector sleeve.

Step 3:

Unscrew the gray colored piston cap to expose the internal piston, piston spring, seal and seal retainer. Remove fully from the Transferpette S lower shaft assembly. Figure 1.4

Step 4:

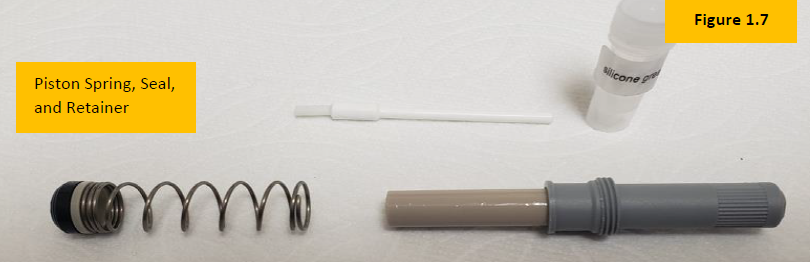

Inspect the piston (1), piston spring (2), seal (3), and retainer (4). Figure 1.5. With a Kim wipe, clean and fully remove old lubricant from the piston, seal, and retainer.

Step 5:

Apply a light, but slightly visible amount of Transferpette S silicone oil onto the piston assembly. Figure 1.6

Step 5A:

Install a new seal assembly onto the retainer.

Transferpette S Reassembly

Step 6:

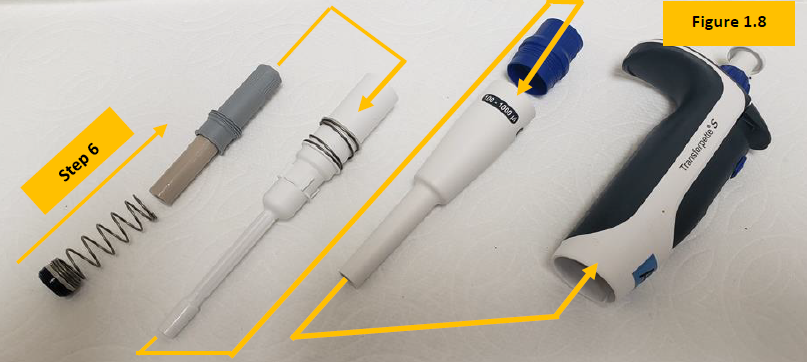

Attach seal retainer to the piston spring. Slide the seal, retainer, and spring back onto the piston with gray cap. Figure 1.8

Step 6A:

Inspect and replace shaft, tip ejector sleeve, piston if needed.

Step 7:

Slide the piston assembly back inside of the lower shaft assembly. Turn and tighten the gray piston cap until the piston assembly is fully secured inside of the shaft. Figure 1.9 and 1.9A

Step 8:

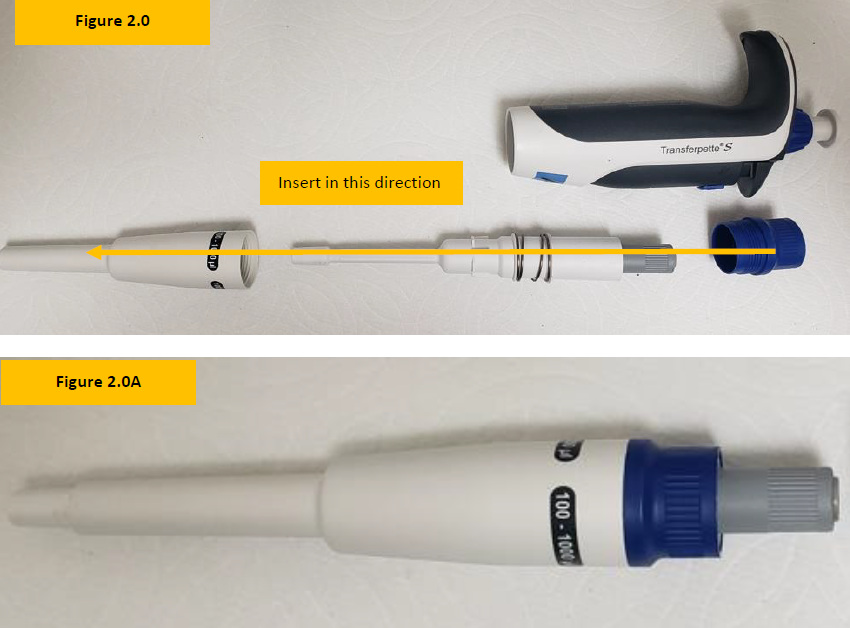

Locate the blue colored coupling nut. Insert the lower shaft assembly into the tip ejector sleeve. Figure 2.0

Rotate and turn blue colored coupling nut until the lower shaft is fully secured inside of the tip ejector sleeve. Figure 2.0A

Step 9:

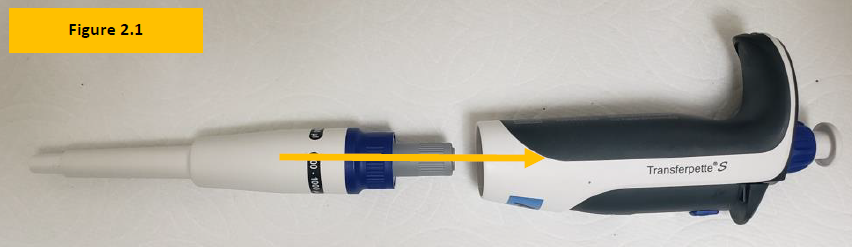

Insert the liquid end assembly into the pipette body opening and rotate the tip ejector sleeve until it is tight with the body.

Step 10:

Once fully reassembled, allow the pipette to equilibrate for at least 60 minutes. After the equilibration period has passed verify accuracy and precision on a 4-5 place analytical balance.

Related Posts:

Transferpette S Parts Decoded

BrandTech Serial Number Format

BrandTech Transferpette Multichannel Nose Cone Part Numbers

Disclaimer: Any action you take using the information on this website is strictly at your own risk. The information herein does not constitute professional advice and is general in nature. We make no warranty that this information will meet your requirements, be safe, accurate, or error-free. Pipette Supplies, Inc. is not responsible for any errors or omissions, any results obtained from the use of this information, or any loss or damage arising out of the use of this information. This site is for educational purposes only.

Fair Use: Copyright Disclaimer under section 107 of the Copyright Act of 1976, allows for “fair use” for purposes such as comments, criticism, teaching, scholarship, news reporting, and research.

Fair use is permitted by copyright statute that might otherwise be infringing.